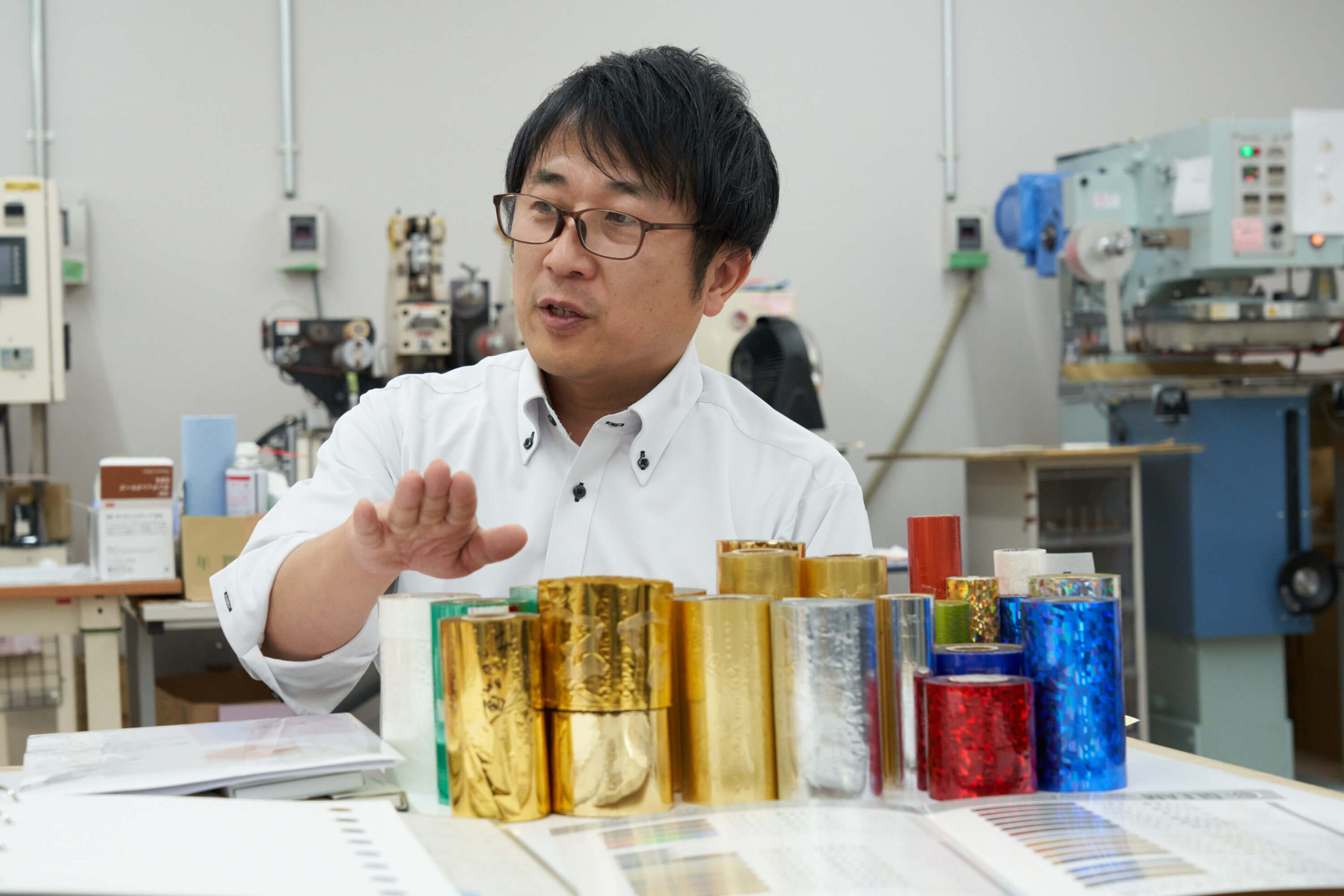

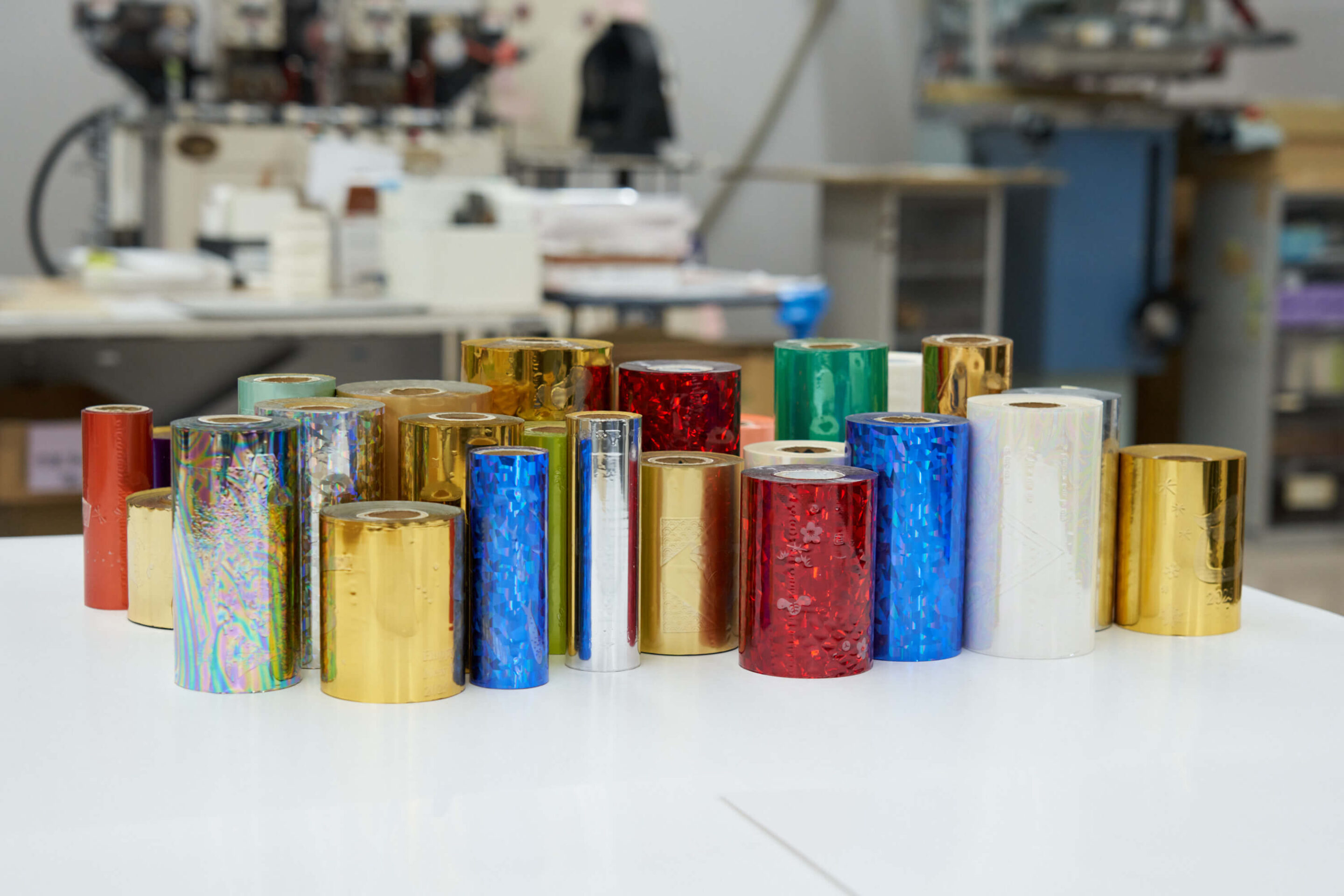

ROKKAKU currently offers an extensive selection of more than 100 foil varieties. Considering differences in texture and stiffness within the same color, the options exceed 200.

#04

ROKKAKU StoryThe Road to a Single Stamp Vol. 2

〈Selecting the best foil for the design〉

Stamping with foil

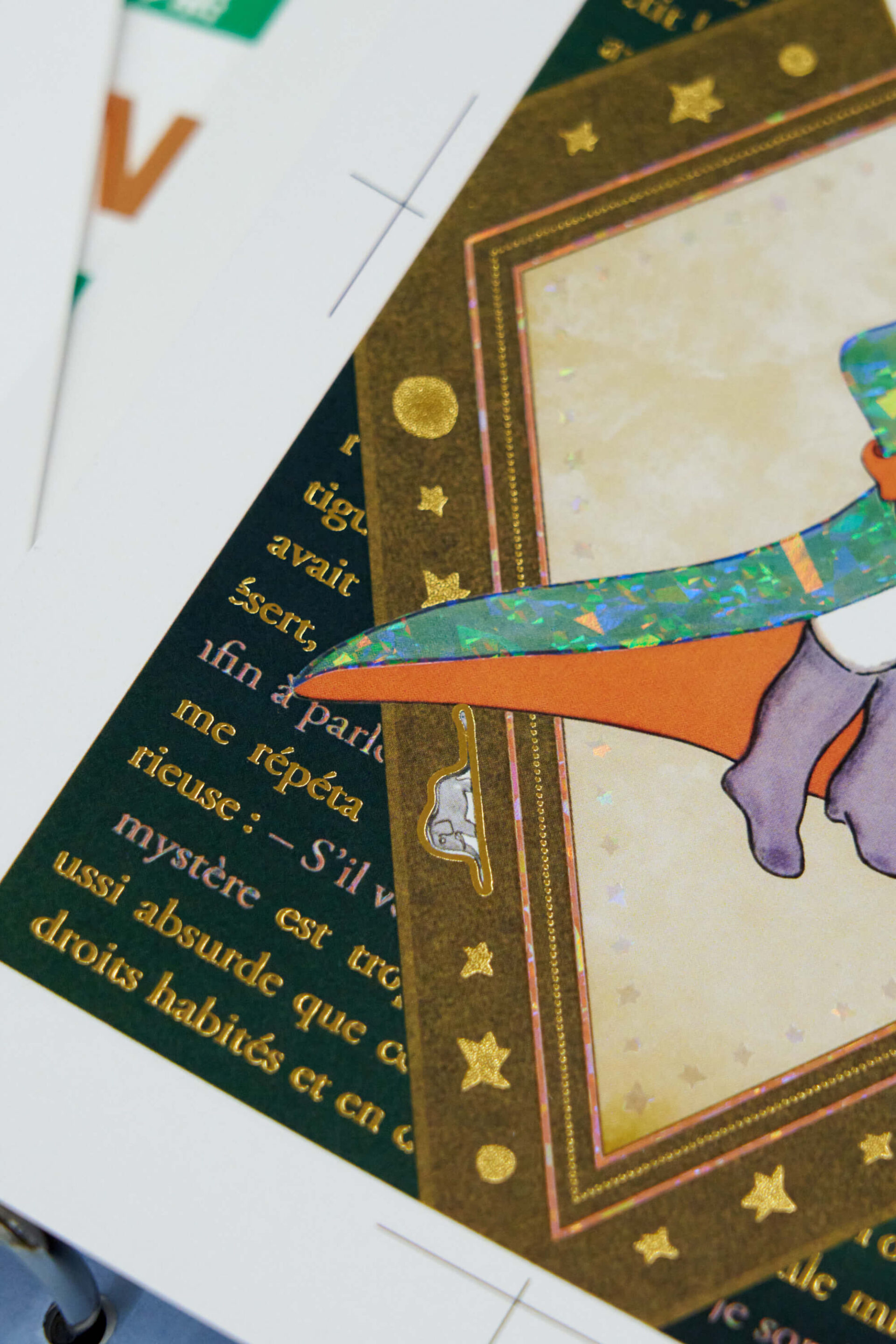

Just like that, foil stamping embellishes the surface of paper with a textured imprint and a glossy finish unmatched by regular ink printing. However, achieving this effect involves multiple steps requiring significant skill and consideration, including design, foil selection, die production, and press setup.

What type of foil stamping process brings out the full brilliance of the foil and adds vibrant color to a design?

Let’s delve into the intricate process that culminates in a lustrous final product.

ー

After the design phase, the next step is selecting the right foil. This stage involves sifting through a variety of foils to find the perfect match for the design. Given that different foils offer varying textures and levels of shine, the choice involves more than color alone; it’s about crafting an overall visual impact that captures attention.

Index

-

01

Understanding the characteristics of over 100 varieties of foil

-

02

Drifting in a sea of inspiration: the sample book

-

03

Check the compatibility of the design with the foil and between foils

-

04

Visually verify dozens of patterns

-

05

COMMENT

Understanding the characteristics of over 100 varieties of foil

The color range is vast; even gold comes in varieties like reddish gold, bluish gold, metallic gold, low-shine gold, and holographic gold. We also provide unique choices like pearlescent and transparent foils that produce a range of shimmering and glossy effects. Our deep understanding of each foil’s characteristics helps us select the perfect match for any given image.

Foils vary not only in color but also in stiffness. Stiff foils are ideal for intricate details such as cutouts and small letters, while more flexible foils adhere better and are preferable for covering larger, flatter surfaces. We consider these technical aspects meticulously to narrow down our extensive list to the most suitable options.

Drifting in a sea of inspiration: the sample book

Beyond the 100 varieties we provide, countless other foils are continuously developed by both domestic and international manufacturers. At ROKKAKU, we obtain sample books from these manufacturers to broaden our options. These samples allow us to directly experience the shimmer and texture of each foil, fostering further inspiration while we keep our initial ideas in mind.

Choosing the right foil from such a vast selection can be daunting, yet it is crucial for finding the perfect match for each design and for expanding the expressive potential of our projects. Even specialty foils, which may initially seem limited in application, can be surprisingly versatile depending on their use. This element of unpredictability adds an exciting dimension to the work we do with foil.

Check the compatibility of the design with the foil and between foils

After exploring the diverse range of foils, we take a careful approach to evaluate each foil’s compatibility with the design and with other foils. Each type has its unique characteristics, and the goal is to create combinations where each foil enhances the others without overshadowing any.

Foils vary not only in color but also in luster, some reflecting light strongly while others are subtler. Achieving the right balance between bright and subdued foils is crucial; overly bright combinations can appear garish, whereas too many dark foils might result in a muted effect.

The choice of foil also depends on the specific areas to be stamped and the delicacy of the details involved. For instance, a low-shine foil might be best for small text to ensure readability, while a holographic foil can add a dynamic range of light effects, even within fine lines. Although it might seem lavish to use a specialty foil for just a small section, such fine details often enable unique expressions that define the final look. We consider these factors carefully as we assess each potential foil application.

Visually verify dozens of patterns

Simulating every detail with numerous foil options is a time-consuming process, but it’s far from the final step. After narrowing down the choices, we create prototypes of various patterns. This critical stage allows us to not only verify which foils best capture the intended image with actual samples but also to confirm the practicality of manufacturing the image with the selected foils. Since each foil type offers a distinct expressive style, we cannot finalize our choice until we’ve physically pressed and assessed its effectiveness.

Typically, we produce about 10 prototypes during this verification phase. Occasionally, further verification is needed after these initial prototypes, leading us to create up to 40 patterns. Because of this extensive testing, deciding on a foil can take anywhere from one to two months.

The selected foil significantly influences the final look of the product. Therefore, we engage in thorough discussions with the designer and all stakeholders, including production and sales teams, to make a well-informed decision. Although selecting the right foil is labor-intensive, this careful deliberation is crucial for ensuring the product’s quality. Once the design and foil are chosen, we proceed to the pressing stage to bring the product to fruition.

COMMENT

We gathered insights from both a designer and a production specialist, who regularly handle a wide variety of foils.

—— What is important to you when selecting the foil?

“Selecting foil is similar to choosing an outfit; it’s about finding what complements the design best. I draw inspiration from the myriad foils in our sample book, allowing my creativity to flourish. Ultimately, I opt for foils that ignite my excitement and seem to speak to me. Sticking solely to foils that are easy to use could make our designs feel monotonous, so I aim to expand our palette and explore the full potential of each option.”

—— What do you think is the appeal of foil selection?

“The process isn’t just about the designer’s choice; it also involves the production operator who physically presses the foil. This stage allows the operator to independently evaluate different foils, ensuring the design’s vision is feasible while also incorporating their own insights and experience. The beauty of this is that the same design can transform dramatically depending on the foil used, making the selection process both a journey of discovery and enjoyment.”